Higher Mallebility

Brand Pipe Fittings withstand higher internal and external pressure without development of cracks as these are produced by using better melting characteristics and heat treatment procedures to provide better ductility.

Brand Pipe Fittings withstand higher internal and external pressure without development of cracks as these are produced by using better melting characteristics and heat treatment procedures to provide better ductility.

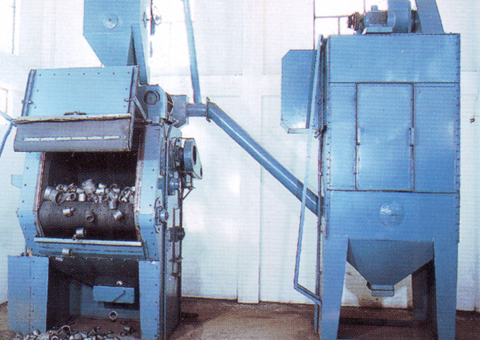

Effective Galvanizing

Brand Fitting are galvanized by highest purity Zinc in the Virgin form by controlled hot dip process. Therefore, these have uniform, clean and continuous coating of Zinc on both internal and external unmachined surface without any black spots and as well as acid spots. In

Brand Fitting are galvanized by highest purity Zinc in the Virgin form by controlled hot dip process. Therefore, these have uniform, clean and continuous coating of Zinc on both internal and external unmachined surface without any black spots and as well as acid spots. In  Brand Pipe Fittings, The thickness of Zinc coating exceeds the minimum specified in the Indian Standard, so as to provide added resistance to corrosion in abnormal weather conditions.

Brand Pipe Fittings, The thickness of Zinc coating exceeds the minimum specified in the Indian Standard, so as to provide added resistance to corrosion in abnormal weather conditions.

SPECIFICATIONS

Material

Blackheart malleable cast iron as per IS : 14329-1995 grade BM-300.

Threads

Threaded as per IS : 554-1999, parallel female and taper male threads.

Finish

Galvanized Finish tested in accordance with provisions contained in IS-4759-1996.

CHAMFERING

Brand Pipe Fittings are chamfered slightly at each thread opening for easy entrance of pipe and correct first thread engagement.

Brand Pipe Fittings are chamfered slightly at each thread opening for easy entrance of pipe and correct first thread engagement.

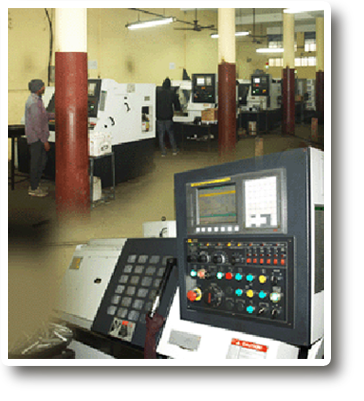

PRECISION THREADING

Brand Pipe Fittings are threaded after galvanizing in order to keep the threads clear and free from dregs .All outlets are threaded simultaneously with the help of HSS ground taps on automatic threading machines to ensure perfect thread alignment at correct angles so

Brand Pipe Fittings are threaded after galvanizing in order to keep the threads clear and free from dregs .All outlets are threaded simultaneously with the help of HSS ground taps on automatic threading machines to ensure perfect thread alignment at correct angles so  Brand Pipe Fittings have threads matching the theoretically correct profile. These dimensions are maintained within closer tolerance limits which ensures

close contact with pipe and eliminates the hazard of leakage. Threads are free from defects such as thin threads, break threads and fins.

Brand Pipe Fittings have threads matching the theoretically correct profile. These dimensions are maintained within closer tolerance limits which ensures

close contact with pipe and eliminates the hazard of leakage. Threads are free from defects such as thin threads, break threads and fins.

TEST & WORKING PRESSURES

Brand Pipe Fittings are tested for leakage at an internal hydraulic pressure of 20 kgf /cm2 or at an internal air pressure of 7.5 kgf/cm2. The maximum working pressure for water is 20Kgf /cm2 and for oil, steam (saturated) gas, air,it is 11 kgf /cm2 at ambient temperature.

Brand Pipe Fittings are tested for leakage at an internal hydraulic pressure of 20 kgf /cm2 or at an internal air pressure of 7.5 kgf/cm2. The maximum working pressure for water is 20Kgf /cm2 and for oil, steam (saturated) gas, air,it is 11 kgf /cm2 at ambient temperature.

QUALITY CONTROLS

The process controls are rigidly enforced throughout the production time to ensure that finished goods are of the highest quality.

RAW MATERIAL TESTING

Important raw materials, other ingredients are tested, prior to their use, for their essential physical and chemical properties, in a well equipped laboratory.

STAGE INSPECTION (VISUAL%)

Raw Casting are inspected for freedom from any such defects as blow holes, hard spots, cold shuts, shifts and sand depth etc.

Annealed Castings are inspected for cracks & distortion.

Galvanized Casting are inspected to ensure that the Zinc Coating is smooth, clean, continuous and free from black and acid spots.

Machined fittings are inspected for any such defects on the threaded portions as thin threads, break threads, fins and pin holes.